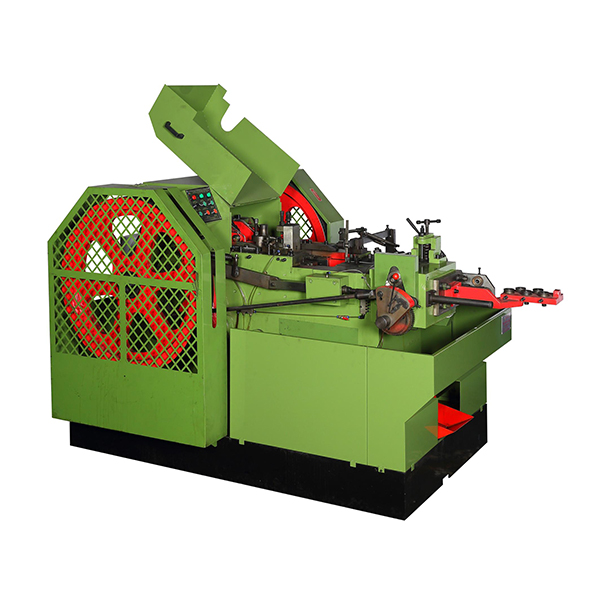

Z12 Series 1-Die 2-Blow Sovuq Sarlavha mashinasi

Asosiy xususiyatlar

1 、Mashinaning asosiy ramkasi va qo'chqor va boshqalar ichki stressni bo'shatish uchun issiqlik bilan ishlov berilgan va uzoq muddatli ishlashda har qanday deformatsiyani oldini olish va barqaror aniqlikni saqlash uchun quyishdan keyin normallashtirilgan;

2, Maksimal qat'iylik va barqaror kesish uchun kesish roliklari har ikki tomondan qo'llab-quvvatlanadi;

3, Tez sozlash va oson parvarishlash bilan zımba slayderining yuqoriga va pastga harakatlanuvchi zarbasini o'zlashtirish uchun oddiy va oqilona dizayn;

4、Overam tipidagi asosiy slayder yuqori qotishma po'latdan yasalgan astarli uzoq va barqaror aniqlikka imkon beradi;PKO zarb qilingan qismlarning chiqib ketishidan oldin qolip hosil bo'lishining oldini oladi;

5, Xavfsizlik pinlari mashina qismlarining shikastlanishiga yo'l qo'ymaslik uchun taqillatish va kesish mexanizmi uchun ishlatiladi;

6、“Inching”, “Yagona zarba” va “Doimiy ishlash” dastgohni asboblar bilan tekislashni ancha osonlashtiradi.

Mahsulot parametrlari

| Model | Maksimal diametri (mm) | Maksimal uzunlik (mm) | Ram Stroke (mm) | Chiqish tezligi (dona/min) | Asosiy qolip (mm) | Kesilgan o'lim (mm) | Punch Die (mm) | To'sar o'lchami (mm) | Mexanik o'lchamlar (mm) | Asosiy dvigatel (kVt) | Sof og'irlik (kg) |

| Z12-3 | 4 | 20 | 40 | 160-190 | ph20*36 | ph13*25 | ph18*50 | 6*25*42 | 1,4*0,75*0,9 | 1.1 | 624 |

| Z12-4 | 5 | 40 | 60 | 140-170 | ph32*60 | ph15*30 | ph25*65/70 | 10*35*72 | 1,8*0,85*1,5 | 2.2 | 1274 |

| Z12-5 | 7 | 60 | 90 | 110-140 | ph32*80 | ph20*35 | ph30*75 | 10*35*72 | 2,3*1,08*1,25 | 3 | 2080 |

| 80 | 110 | 90-110 | ph32*100 | ph20*35 | ph30*80 | 10*35*72 | 2,4*1,15*1,35 | 2145 | |||

| 100 | 130 | 80-100 | ph35*120 | ph20*35 | ph30*80 | 10*35*72 | 2,5*1,15*1,35 | 2210 | |||

| 150 | 190 | 80-100 | ph40*180 | ph20*35 | ph35*100 | 10*35*72 | 2,6*1,15*1,35 | 2990 | |||

| Z12-6 | 9 | 90 | 120 | 80-100 | ph50*120 | ph24*40 | ph35*100 | 12*35*77 | 2,7*1,4*1,6 | 5.5 | 3380 |

| 120 | 150 | 70-90 | ph50*150 | ph24*40 | ph35*100 | 12*35*77 | 2,8*1,4*1,6 | 3640 | |||

| 150 | 190 | 60-70 | ph50*180 | ph24*40 | ph35*100 | 12*35*77 | 3,0*1,4*1,6 | 4160 | |||

| 170 | 230 | 50-60 | ph50*220 | ph24*55 | ph35*120 | 12*35*77 | 3,2*1,4*1,6 | 4360 | |||

| 200 | 250 | 40-50 | ph50*240 | ph24*55 | ph35*120 | 12*35*77 | 3,65*1,4*1,65 | 4940 | |||

| 250 | 290 | 30-45 | ph50*290 | ph24*60 | ph35*140 | 12*35*77 | 3,7*1,5*1,7 | 5460 | |||

| Z12-8 | 11 | 120 | 160 | 60-80 | ph60*160 | ph28*45 | ph40*120 | 12*42*90 | 3,75*1,6*1,8 | 7.5 | 4940 |

| 150 | 190 | 60-70 | ph60*190 | ph28*45 | ph40*120 | 12*42*90 | 3,9*1,6*1,8 | 6240 | |||

| 200 | 250 | 40-50 | ph60*240 | ph28*60 | ph40*150 | 12*42*90 | 4,15*1,6*1,85 | 6500 | |||

| 250 | 290 | 30-45 | ph60*290 | ph28*60 | ph40*150 | 12*42*90 | 4,3*1,6*1,9 | 7800 | |||

| Z12-10 | 13 | 120 | 160 | 50-60 | ph80*160 | ph35*50 | ph50*150 | 16*55*115 | 4,8*1,8*1,32 | 11 | 8450 |

| 180 | 230 | 50-60 | ph80*220 | ph35*50 | ph50*150 | 16*55*115 | 4,8*1,8*1,32 | 8650 | |||

| 220 | 270 | 40-50 | ph80*260 | ph35*50 | ph50*150 | 16*55*115 | 5,0*1,8*1,32 | 9100 | |||

| Z12-12 | 15 | 150 | 190 | 40-50 | ph88*200 | ph45*60 | ph60*180 | 18*60*125 | 5,2*1,9*1,8 | 18.5 | 14040 |

| 200 | 250 | 30-40 | ph88*260 | ph45*60 | ph60*180 | 18*60*125 | 5,2*1,9*1,8 | 14300 | |||

| 280 | 330 | 30-40 | ph88*340 | ph45*60 | ph60*180 | 18*60*125 | 5,2*1,9*1,8 | 15600 | |||

| 300 | 350 | 25-35 | ph88*360 | ph45*60 | ph60*180 | 18*60*125 | 5,2*1,9*1,8 | 15860 |